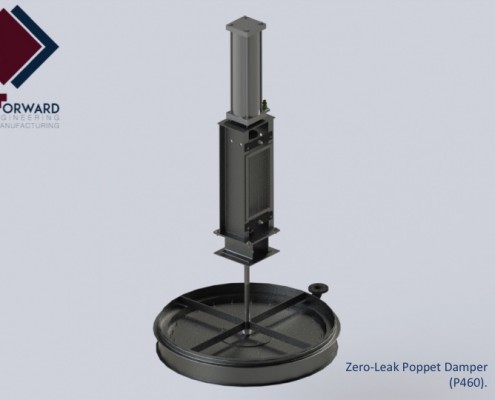

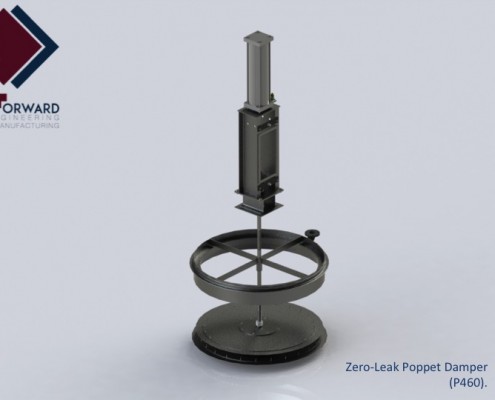

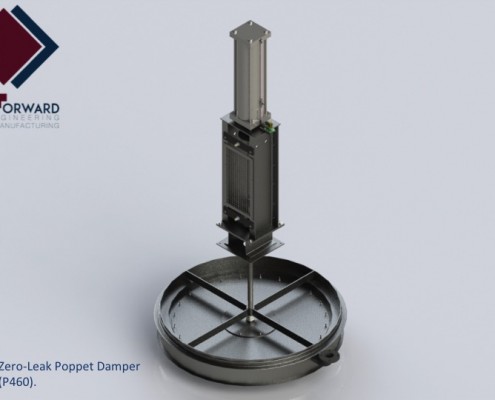

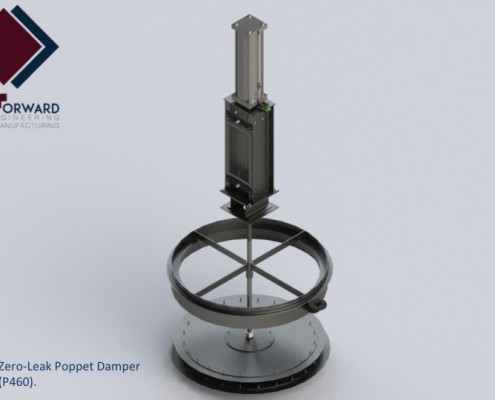

The FE&M double poppet is designed to provide zero-leakage utilizing two (2) poppet blade assemblies attached to the same shaft and a seat assembly with two (2) seats.

Zero leakage is attained by injecting ambient air into the poppet seat between the two blades at a pressure 3 Inches W.C. greater than the upstream static pressure to ‘block’ gas leakage thus providing 0.0% leakage. The volume of sealing air injected is 200% of the calculated minimum volume.

Standard actuators are pneumatic cylinders. Controls include directional valves and position indicator switches. Optional electrical enclosures and wiring is available connecting controls and limit switches.

Various mounting orientations and flow directions are available to accommodate a customer’s actual compartment design.

Download Brochure