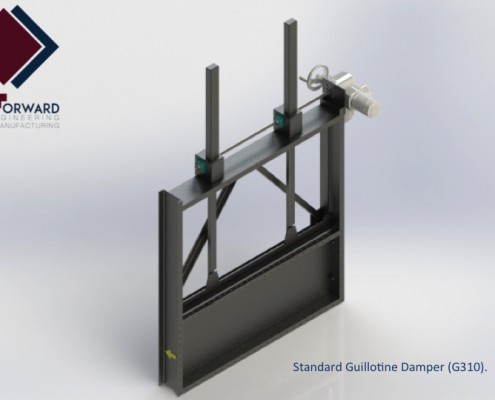

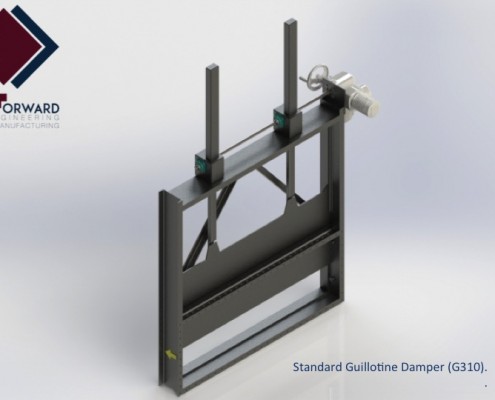

FE&M guillotine dampers are engineered to provide reliable isolation of industrial process gas systems.

Blades, frames, seals, drives and supports are carefully engineered to ensure service longevity at maximum design pressure and temperature. Frames are designed to minimize deflection while meeting allowable stress values. Blades are constructed of flat plate for low temperature applications and engineered blades for high-temperature.

Combined bending, shear and thermal stresses at maximum conditions are maintained within ASME allowable stresses. The standard seat is a bar seat welded to frame sides and bottom with flex metal ambient seals. Should particulate be a concern, an option is available for flex metal seals with a large cleanout box at the bottom.

Downstream leakage is expected to range from 5% to 0.10% leakage depending on size and operating conditions. Leakage to ambient varies from 0.5% to 0.0% with optional frame enclosure.

Rugged rack and pinion drive systems are standard on all FE&M guillotine dampers. Smaller dampers have single rack systems. Larger dampers have dual rack and pinion systems driven with a single actuator.

Manual, electric, pneumatic and hydraulic actuators are available depending on customer requirements. Directional controls, motor starters and position indicators are available as options.

Dampers may be installed in any position with blade entry at duct top, bottom or side. Frames may be likewise oriented vertical or horizontal.

Download Brochure