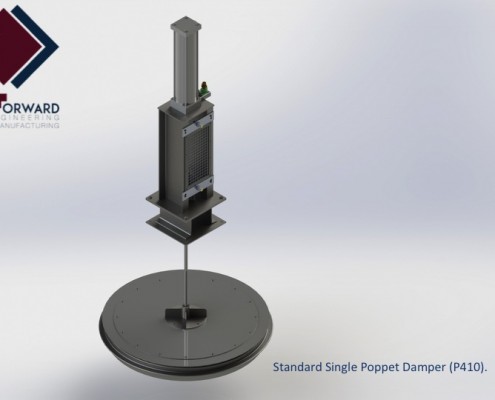

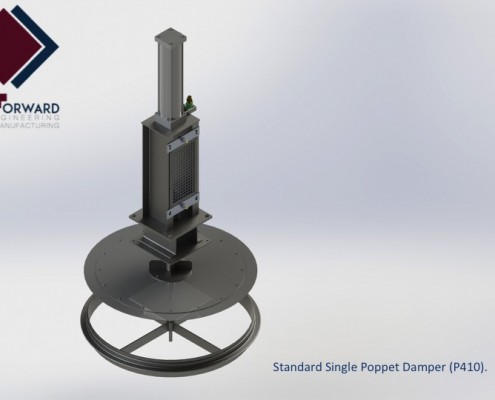

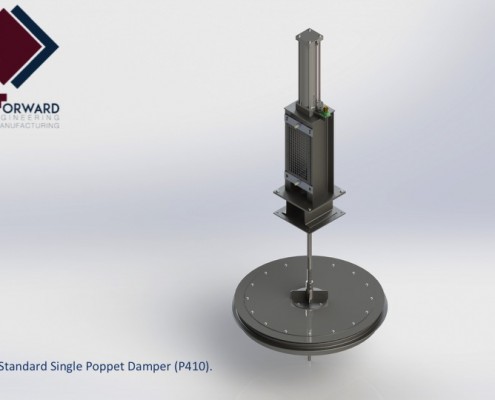

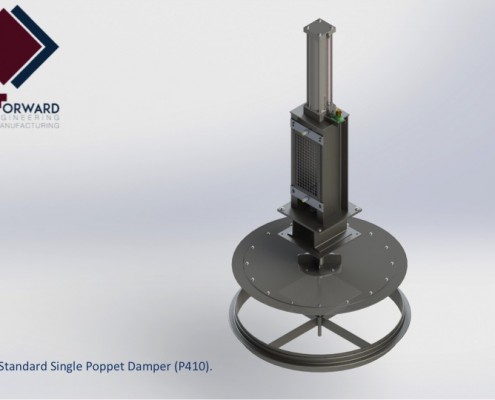

This is the most basic of poppet dampers having a single blade and seat.

The standard poppet blade assembly has stiffened plates bolted together to form a rugged and reliable assembly. An optional flexible metal alloy seal is available should corrosion be a problem.

Poppet blades are conservatively engineered to remain flexible while maintaining bending stresses within ASME allowable values.

The seat is a rolled plate stiffened with a mounting angle, internal shaft guide and radial supports. An optional alloy seat edge is available for corrosive applications. A heavy-duty drive assembly rigidly supports the pneumatic cylinder, shaft and packing gland. An optional insulation standoff is available to raise the drive assembly above insulation to reduce heat loss from the fabric filter compartment. The standard packing gland is a 2-bolt design having formed packing rings, the number of which depends on the maximum design pressure.

Leakage through the packing gland is zero (0) at any blade position at maximum design pressure.

Standard actuators are pneumatic cylinders. Controls include directional valves and position indicator switches. Optional electrical enclosures and wiring is available connecting controls and limit switches.

Various mounting orientations and flow directions are available to accommodate a customer’s actual compartment design.

Download Brochure