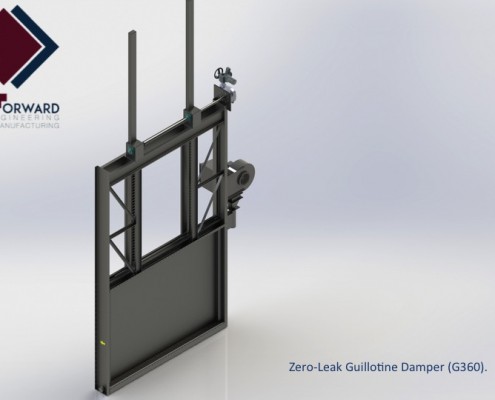

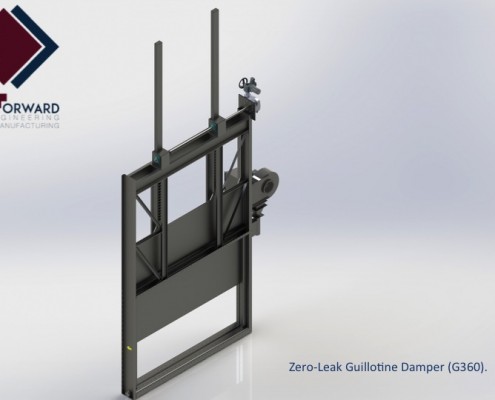

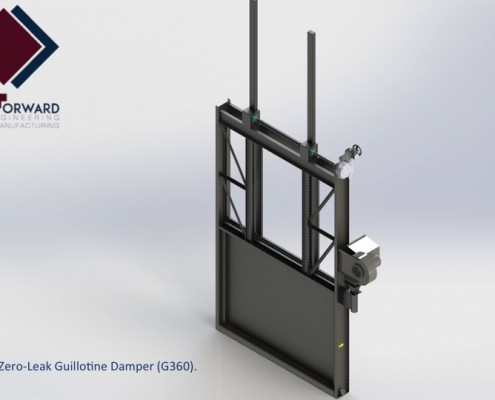

FE&M zero leak guillotine dampers are engineered to provide 100% isolation of process gas systems.

Blades, frames, seals, drives, supports and seal air systems are carefully engineered to ensure performance and longevity at maximum design pressure and temperature. Frames are designed to minimize deflection while providing a rigid support structure. Blades are constructed of flat plate for low temperature applications and die-formed plate for high-temperature.

Combined bending, shear and thermal stresses at maximum conditions are maintained within ASME allowable stresses. Dual flexible metal seals are engineered and precisely fabricated and assembled to ensure seating of blade during isolation.

Zero (0.0%) leakage downstream and to ambient is achieved utilizing a seal air purge. Seal air fans are sized to provide 200% of sealing volume at 3 Inches W.C. greater than gas pressure effectively blocking process gas from leaking downstream. Access to seals is either internal to duct or external to duct depending on customer preference.

Rugged rack and pinion drive systems are standard on all FE&M guillotine dampers. Smaller dampers have a single rack system and larger dampers have dual rack and pinion systems. Both single and dual rack and pinion drive systems are driven with a single actuator.

Manual, electric, pneumatic and hydraulic actuators are available depending on customer requirements. Directional controls, motor starters and position indicators are available as options.

Dampers may be installed in any position with blade enFE&M zero leak guillotine dampers are engineered to provide 100% isolation of ducts.

Download Brochure