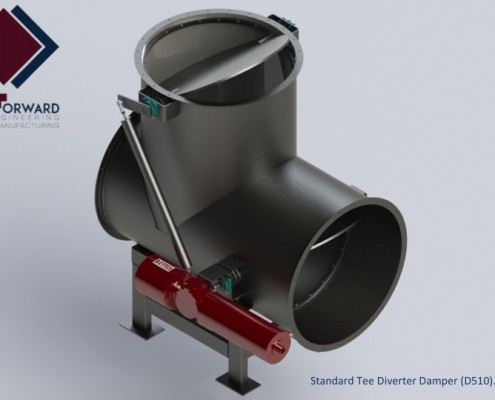

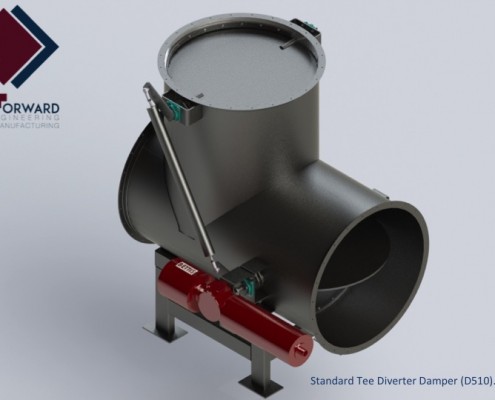

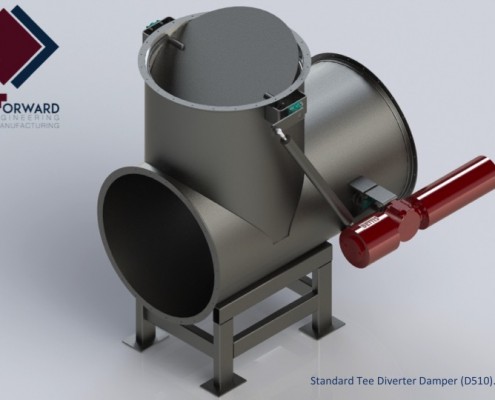

The FE&M standard tee diverter damper utilizes two (2) butterfly dampers arranged 90 degrees from one another to divert, control and isolate gas turbine (GT) exhaust.

There is one inlet flange and two outlet flanges on the damper duct tee onto which each butterfly damper is mounted. The heavy-duty duct tee is engineered to provide a rigid structure on which to mount dampers, actuation, controls and indicators. It is designed for external insulation.

An optional support stand is available to provide a rigid base for the diverter damper.

Damper blades are flat plate inspected to ensure flatness to desired tolerances. Each blade is aligned with stub shafts on a fixture prior to welding to ensure blade rotates concentric with bearings. Efficient blade stiffeners enable the tee diverter to reliably isolate virtually any small gas turbine with very low static pressure loss. Bearings are carefully selected for maximum gas temperature considering heat transfer through gland and shaft. The packing gland is a 2-bolt design having formed packing rings, the number and material of which depends on maximum design pressure and temperature.

Leakage through the packing gland is zero (0) at design pressure and temperature. A variety of seats and blades are offered to provide isolation from 0.5% to 0.0% leakage downstream. While a butterfly damper is ideal for isolation, it is also used for control of gas as well.

Standard actuators include pneumatic, electric, hydraulic and manual systems. Controls include directional valves for 2-position operation, positioners (electric & pneumatic) for flow control, position transmitters and position indicator switches.

Download Brochure