FE&M single flap diverter dampers are specifically engineered for harsh and demanding service in gas turbine combined cycle systems. Each and every design detail has been carefully engineered with emphasis on product quality, functionality, longevity and efficiency. A FE&M Flap Diverter will provide up to 99.9% sealing efficiency without seal air and 100% with seal air at either diverter outlet.

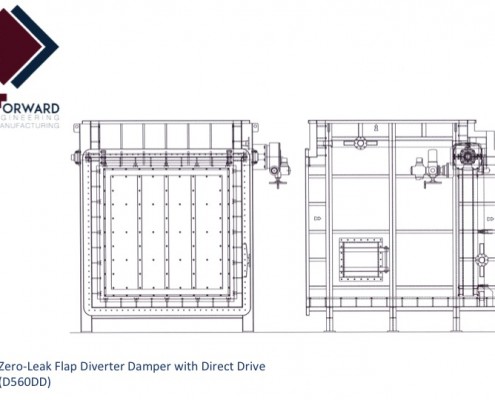

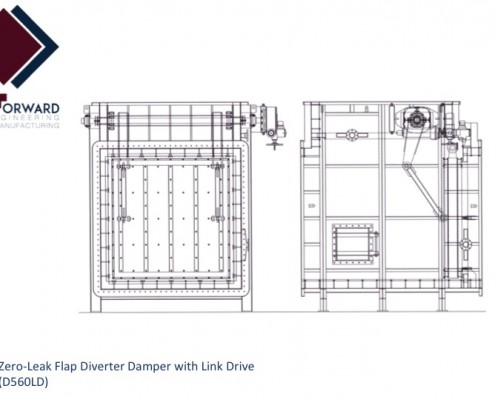

Flap diverter dampers are available with either direct drive or linked drive systems depending on diverter size and operating conditions. All diverter dampers are fully assembled, calibrated and tested at the factory at final inspection prior to shipment. A video is provided to customers of all tests conducted on each diverter damper.

Small to medium diverter dampers will be shipped to site in one assembly. Large diverter dampers will be disassembled and ‘match-marked’ into four to six sub-assemblies to accommodate loading and transport to project site or port of exit. Installation manuals, visual aids and company technicians are available to assist in simple on-site reassembly of the diverter.

Standard actuators include electric and hydraulic with pneumatic actuators used on smaller diverters. Controls include directional controls for 2-position operation, digital positioners (electric & hydraulic) for gas flow control, position transmitters and position indicator switches.

Download Brochure (Direct Drive)

Download Brochure (Link Drive)