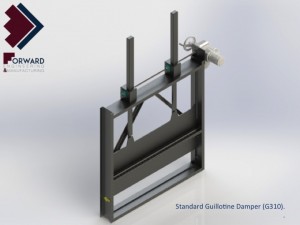

Forward Engineering & Manufacturing LLC guillotine dampers are engineered with state of the art design features to all applicable codes and standards including ASME Boiler and Pressure Vessel Code, ASTM and AISI:

- Engineered for Service Longevity – All guillotine dampers are carefully engineered and manufactured to highest quality standards to assure installed performance and longevity.

- Blades – Guillotine damper blades are engineered to provide reliable low and zero-leakage isolation of process gas systems. Blades are fabricated to exacting flatness standards of ½ thickness when hung vertically. Thermal expansion of blade is accommodated in the frame and seal design to eliminate binding and ensure reliable operation. Engineered blades are offered as an option for high-temperature gas systems. Combined bending, shear and thermal stresses at maximum design conditions are kept well within ASME allowable stresses to ensure performance and longevity.Blade deflection is limited according to seal configuration and/or customer requirements.

- Seals – Flexible metal seals are constructed of high-strength corrosion-resistant alloys for sealing reliability and longevity. Seals may be accessed either internally or externallydepending on customer’s preference. FE & M zero-leak guillotine dampers do not require drive frame be enclosed to achieve zero-leakage. A drive frame enclosure is available as an option to customers.

- Rack and Pinion Drive System – Reliable single or dual rack and pinion drive systems are standard. Each is engineered to be maintenance-free for the life of the damper in the process gas system. A single actuator operates single and dual rack & pinion drive systems. Actuators may be positioned on either left or right sides when viewing downstream. Rack, pinions, bearings, shaft and housing are designed to accept full actuator stall output with one rack incapacitated. Racks are designed such that the can be fully encased in a drive enclosure should that option be selected.

- Frame – All frames are engineered for maximum design combined dead and live loads. FE & M frames provide a rigid structure on which drive and sealing loads can be supported.

Leave a Reply

Want to join the discussion?Feel free to contribute!