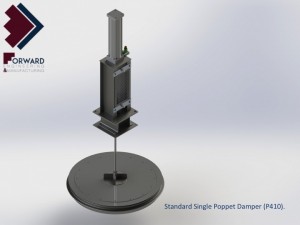

Forward Engineering & Manufacturing LLC poppet dampers are engineered with state of the art design features to all applicable codes and standards including ASME Boiler and Pressure Vessel Code, ASTM and AISI:

- Engineered for Service Longevity – All poppet dampers are carefully engineered and manufactured to highest quality standards to assure installed performance and longevity.

- Reinforced Poppet Blade – Poppet dampers are carefully engineered with stiffened plate blades with optional flexible alloy seals. The design is a rugged solution for erosive high temperature process gas systems. All maximum bending, shear, thermal and combined stresses conform to ASME allowable stress values. Blade deflection under load is engineered for the particular seat design to achieve required gas leakage,

- Poppet Shaft – Poppet shafts are designed considering combined bending and shear stresses imposed by the actuator at maximum static pressure and maximum temperature. Allowable stresses are per ASME.

- Seats – Metal seats are engineered for maximum longevity in erosive service. Alloy seat edges are available should corrosion also be a consideration.

- Packing Gland – The standard packing gland is a 2-bolt design having formed packing rings, the number of which depends on the maximum design pressure. Leakage through the packing gland is zero (0) at any blade position at maximum design pressure.

- Frames – All frames are carefully engineered and fabricated to ensure precise dimensional tolerances are maintained for each application. Damper frames must provide a platform on which the damper reliably isolates flow.

Leave a Reply

Want to join the discussion?Feel free to contribute!